KFC Bucket

Mechanical Design

2024

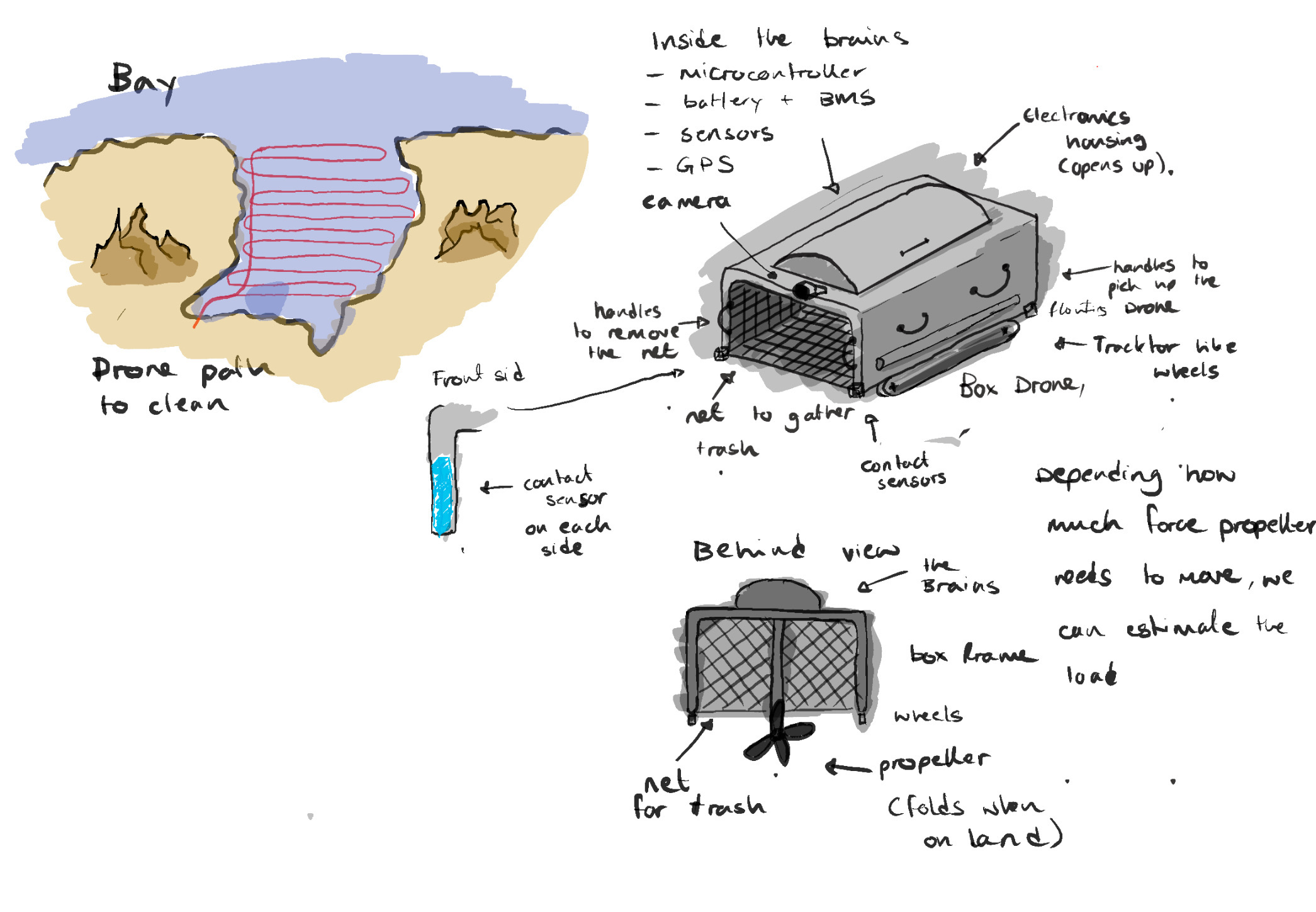

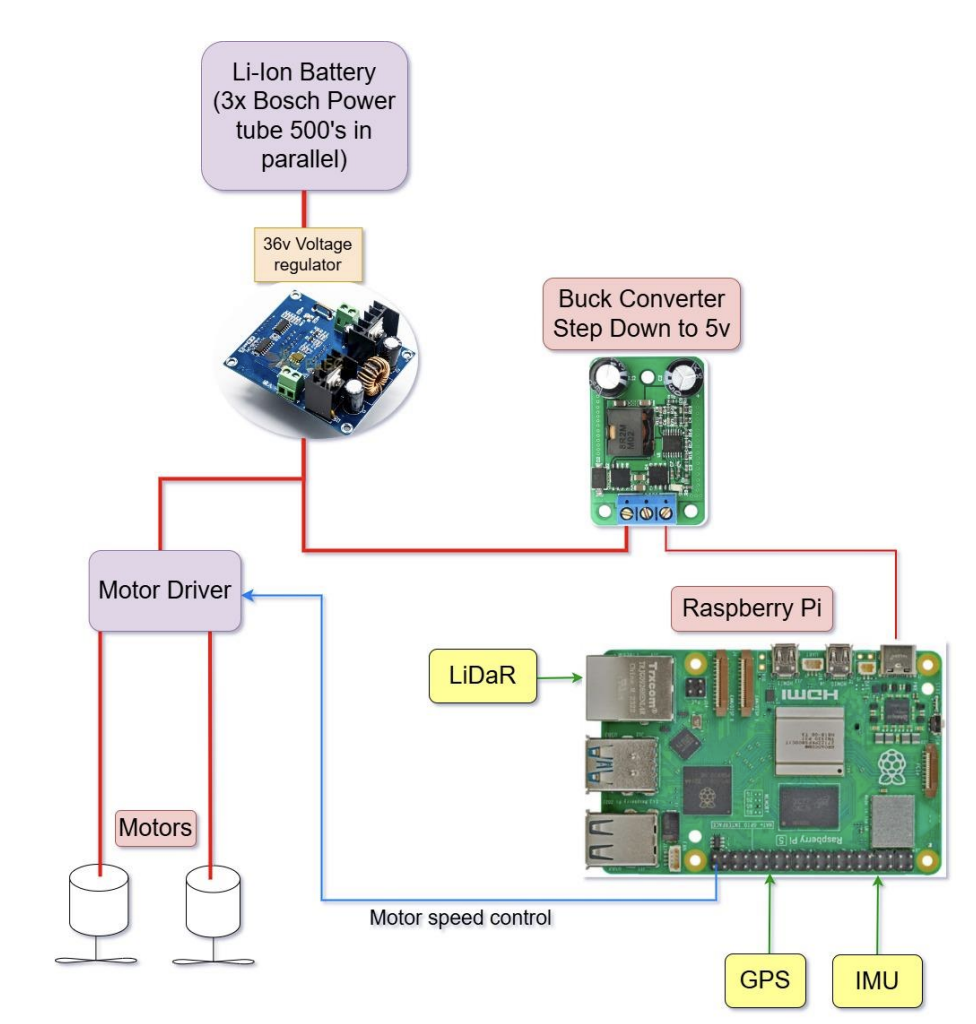

The Kleanup for Koastlines (KFC) project developed an autonomous water drone to remove floating plastic debris, supporting UN SDG 14. A six-member team designed a hexagonal HDPT hull housing dual 36 V brushless motors and spiral propellers, powered by parallel Bosch 500 Wh batteries for over 2 hours at up to 2 m/s. Perception blends Ublox NEO-M8N GPS, MPU-9250 IMU, and TF02-Pro LiDAR (40 m range). Custom control software fuses waypoint navigation, PI steering, and Dijkstra-based rerouting to dynamically intercept debris. Prototyping and simulations confirmed buoyancy, stability, and fully autonomous operation in marine conditions.

I originated the drone’s core concept, selected its GPS, IMU, and LiDAR sensors for reliable autonomy, and implemented navigation algorithms integrating waypoint planning, PI control, and Dijkstra-based obstacle rerouting.

I worked alongside Marcus Gatt to map out every power rail and signal path—selecting the step-down converter to reliably feed the Raspberry Pi and sensors, and routing the high-current lines to the motor driver for our dual-propulsion system.

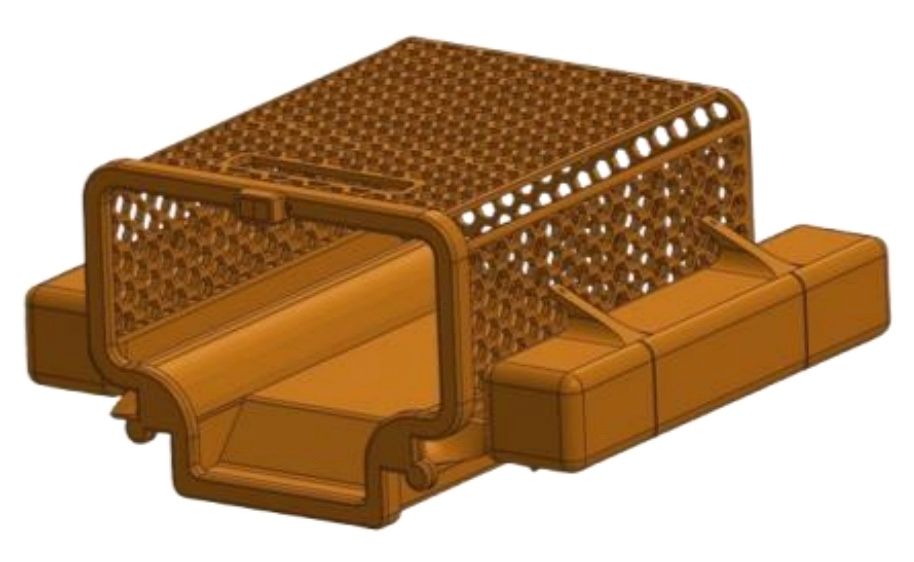

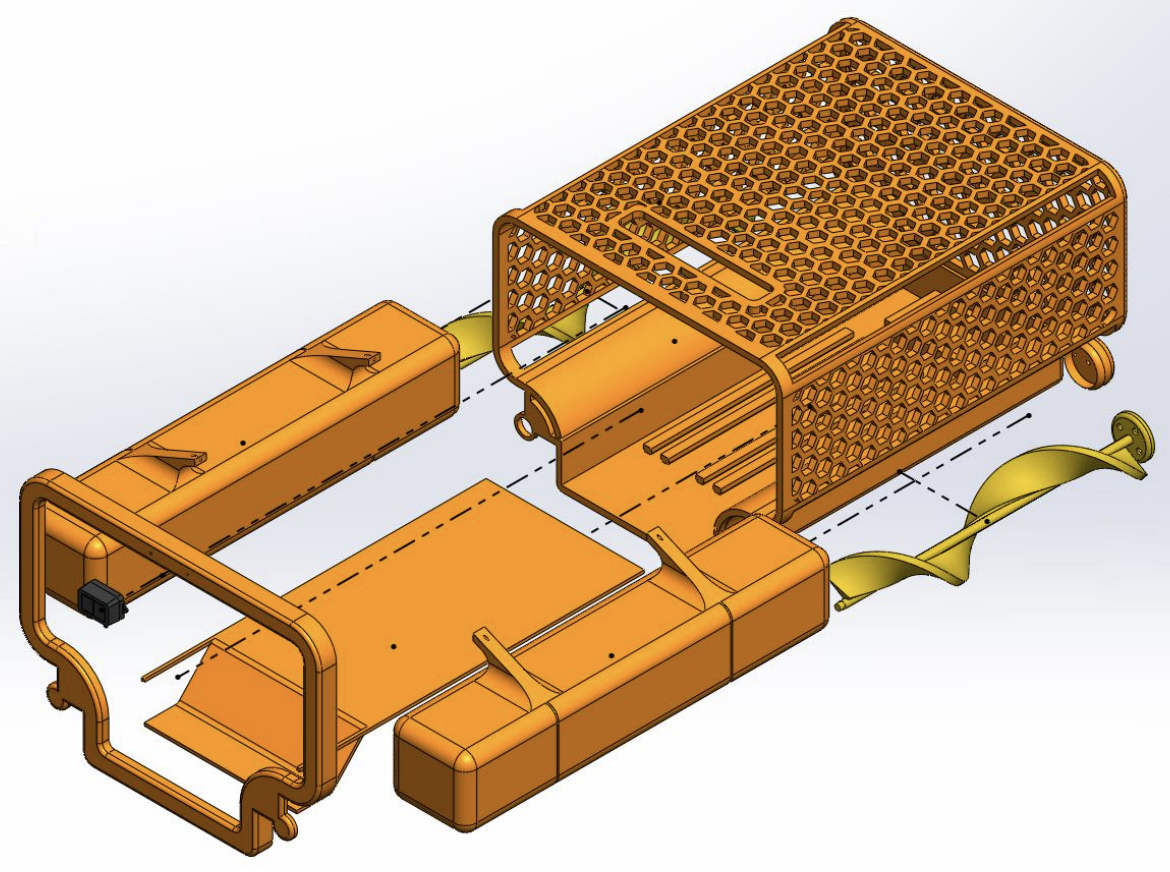

Dave Cooper and I collaborated on the detailed SolidWorks model—defining part clearances for rapid assembly and ensuring each compartment aligned precisely for optimal buoyancy and easy maintenance in the field.